Providing the full

engineering solution

to customize your needs.

engineering solution

to customize your needs.

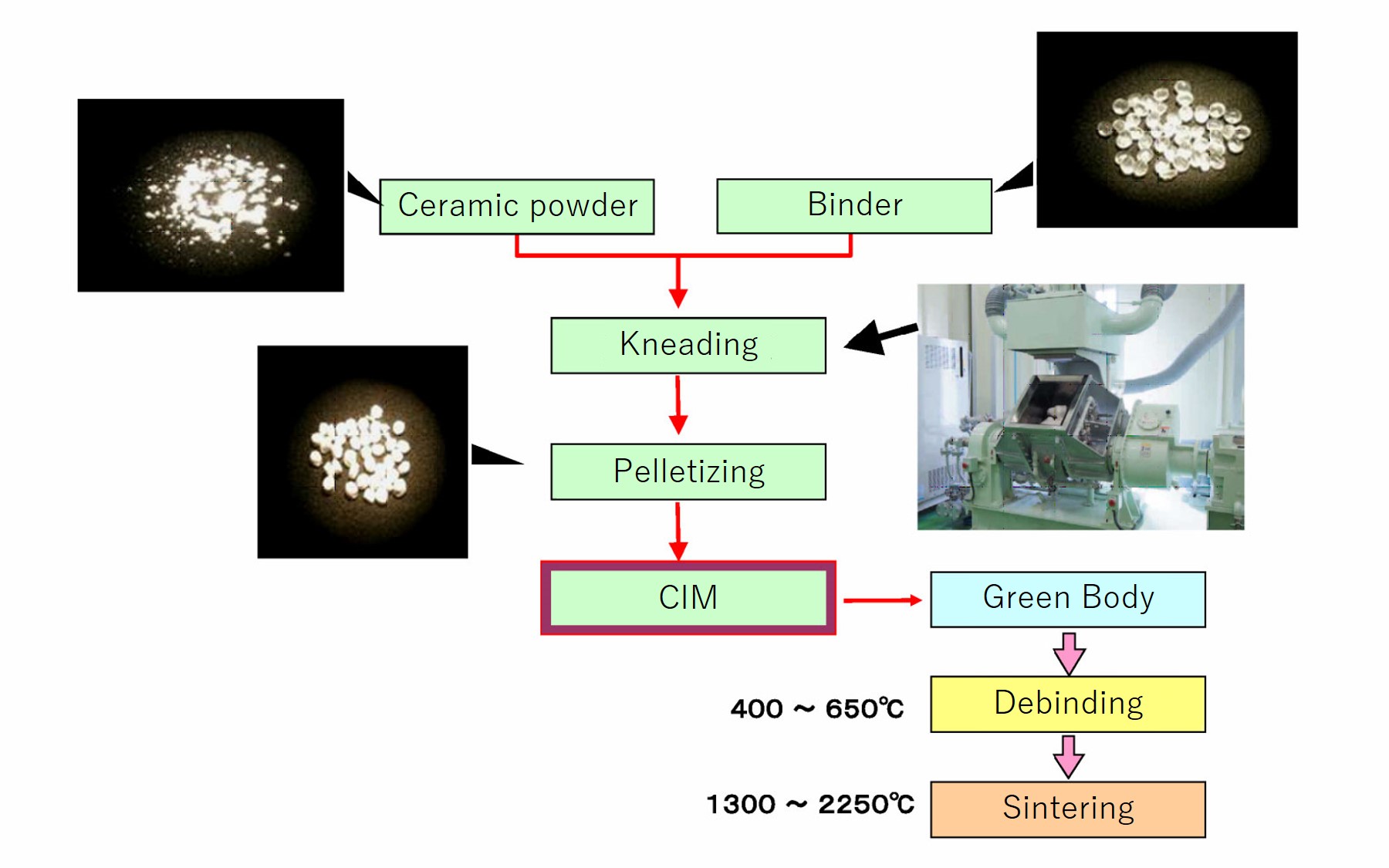

Production Process

Injection Molding Process

By using the CIM technology, we realize the product in the various fields as industrial and decoration use. Complex shape can be produced by our technology. This expands our future potential.

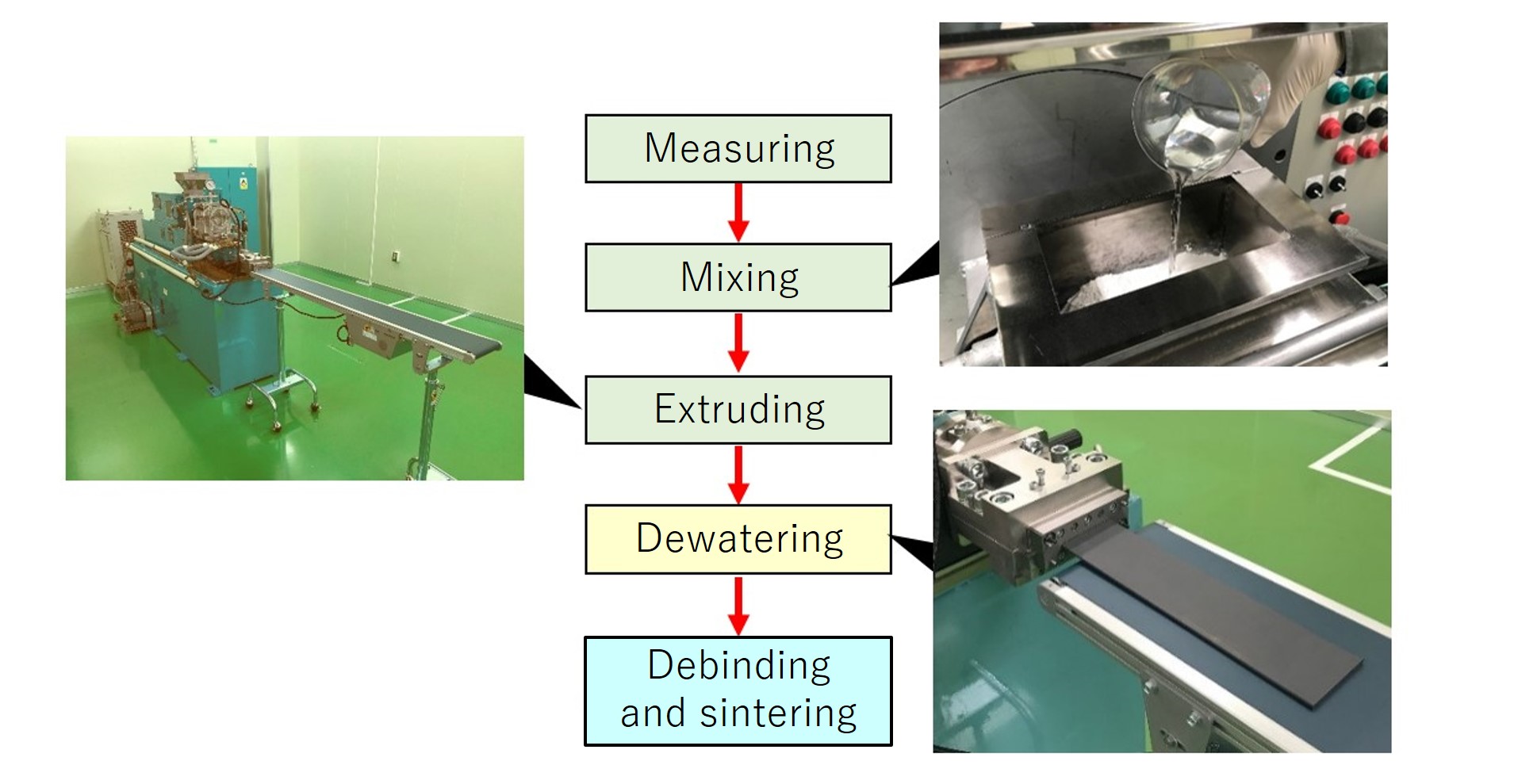

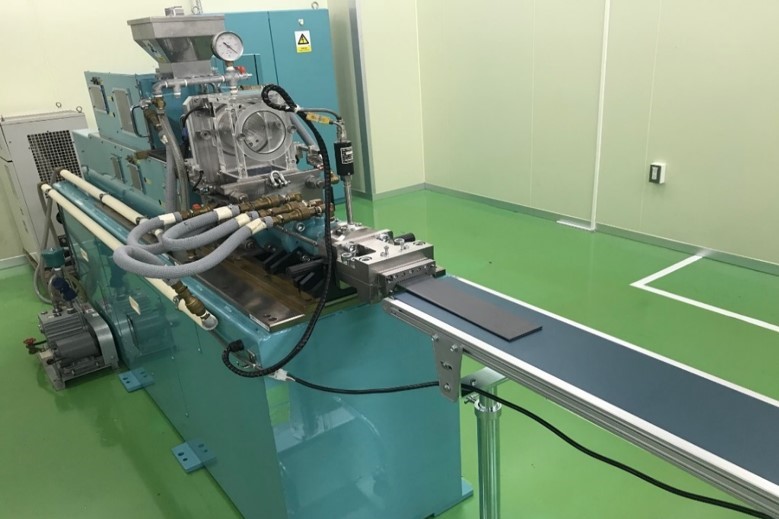

Extrusion Molding Process

By mixing the ceramic powder with water and binder, we can give the green body easy-forming feature. After the compounding process, we use the mold to extrude the green body. This process is suitable to produce the product having the same cross section shape such as pipe, sheet, film and honeycomb.

Key Products

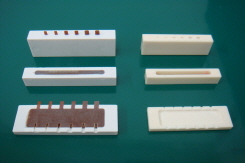

Injection Molding

・Material

Translucent Alumina

Color Zirconia

High Thermal conductivity Product (AlN)

Electric Conductive Part

Si3N4

Porous Ceramic

・Shape

Undercut Shape Product (Alumina/Zirconia)

Small Hole Nozzle

(min 0.1mm)

Large Size

Product

Large Size

Product

Hollow Shape Product

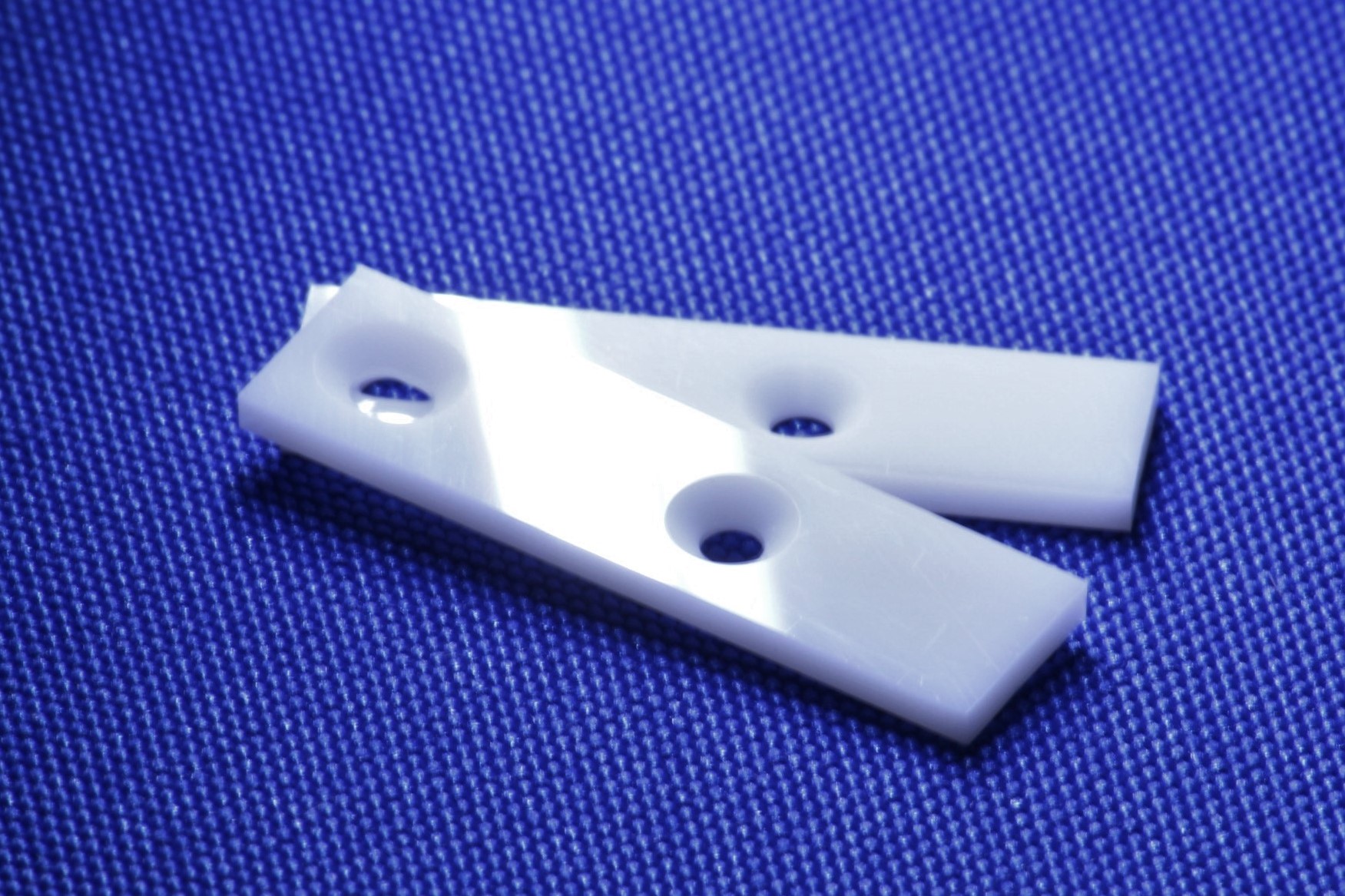

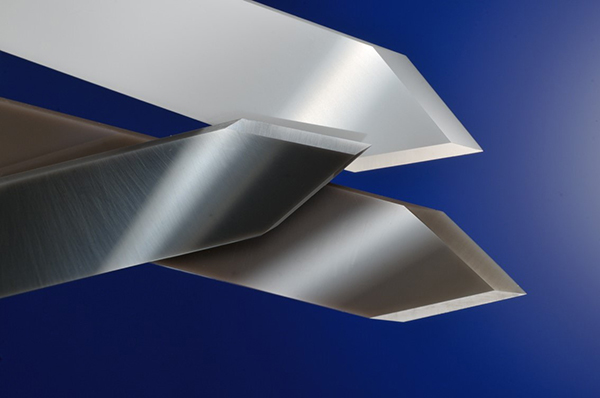

Zirconia Cutter

Blade

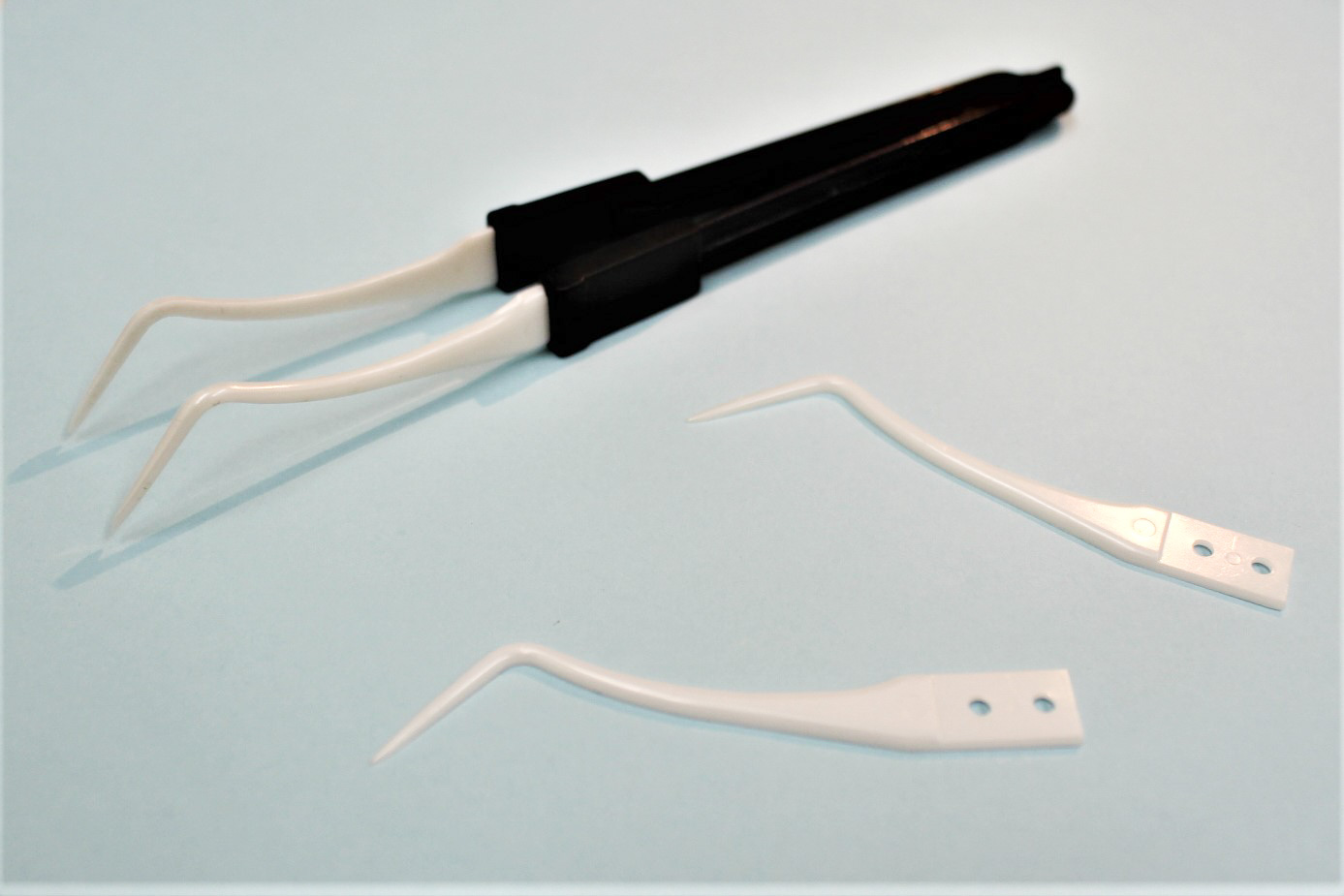

Pinsetter

Others

Powder Stamped Product

Cold Isostatic Pressed Product

Production Facilities

As the CIM manufacturer, we have the most number of facilities force in Japan.

We own 15 sets of 30~100ton injection machine, connected to the central system to monitor the production and quality data.

・Realizing the traceability and quality improvement

・Analyzing the defect cause and confirming the production stability

・Realizing the cost reduction and the production availability improvement

By manufacturing in clean room, we can well control the quality stability of our ceramics product.

・Stabilizing the molding parameters

・Preventing the contamination

・Long-term storaging the raw material in the stable condition

We have in-house mold shop to support our production activities.

Injection Machine

Extruder

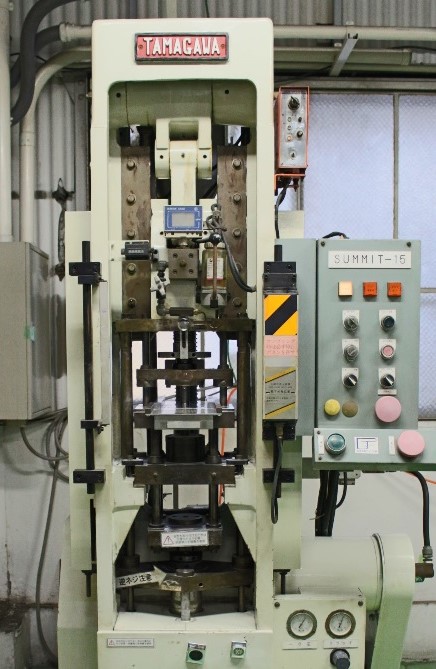

Powder Stamping Machine

Automated Take-Out System

Debinding Furnace

Debinding Furnace

Debinding and Sintering Furnace

Vacuum Sintering Furnace

(Max Temperature 2250℃)

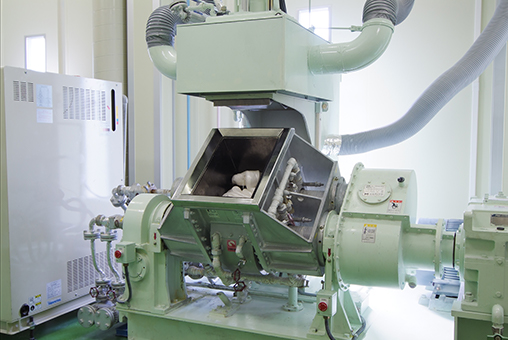

Dispersion Kneader (20L)

Surface Grinding Machine

Double Head Grinding Machine

Centerless Polishing Machine

Machining Center

Sandblasting Machine

Ultrasonic cleaning equipment

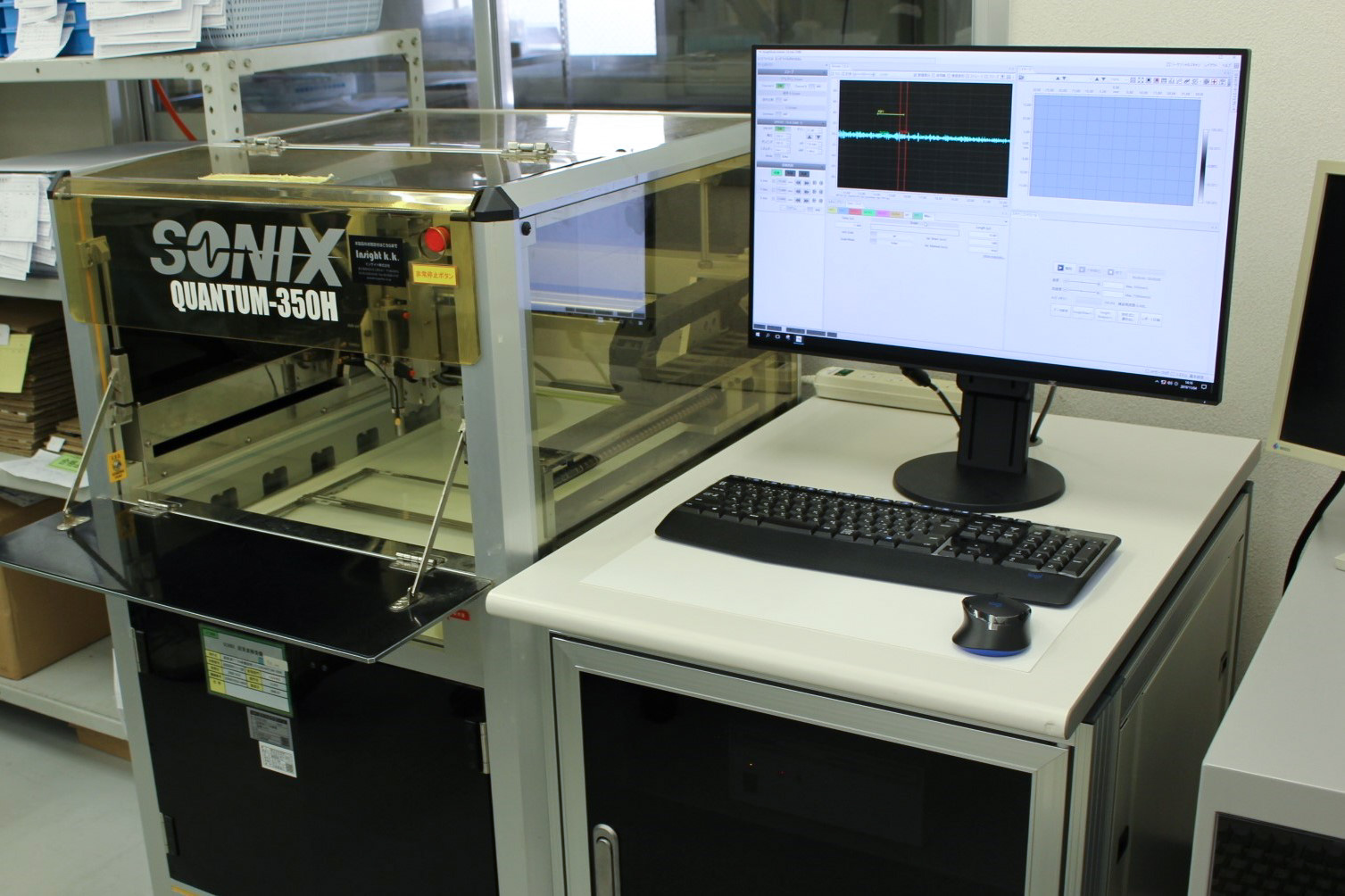

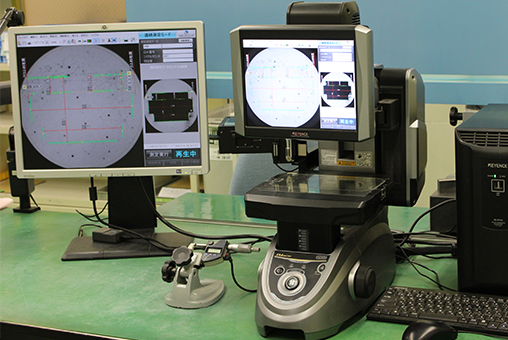

Plenty of R&D equipments and the systemized Quality Control

Striving the high-functioning and high-quality with utilizing the various equipments and devices

Three-dimensional Measuring Machine

Image Measuring Device

Lab Plastomill

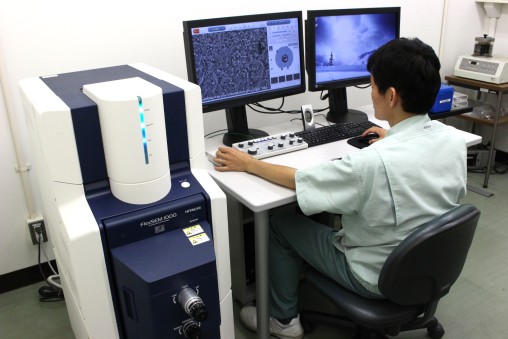

Scanning Electron Microscope

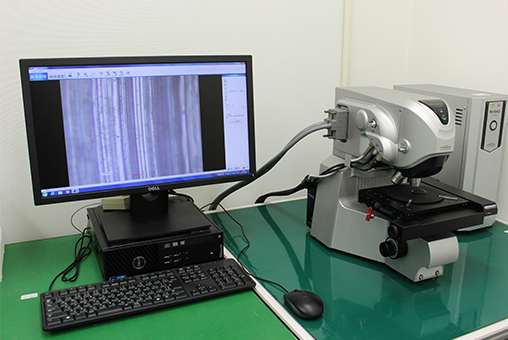

Laser Microscope

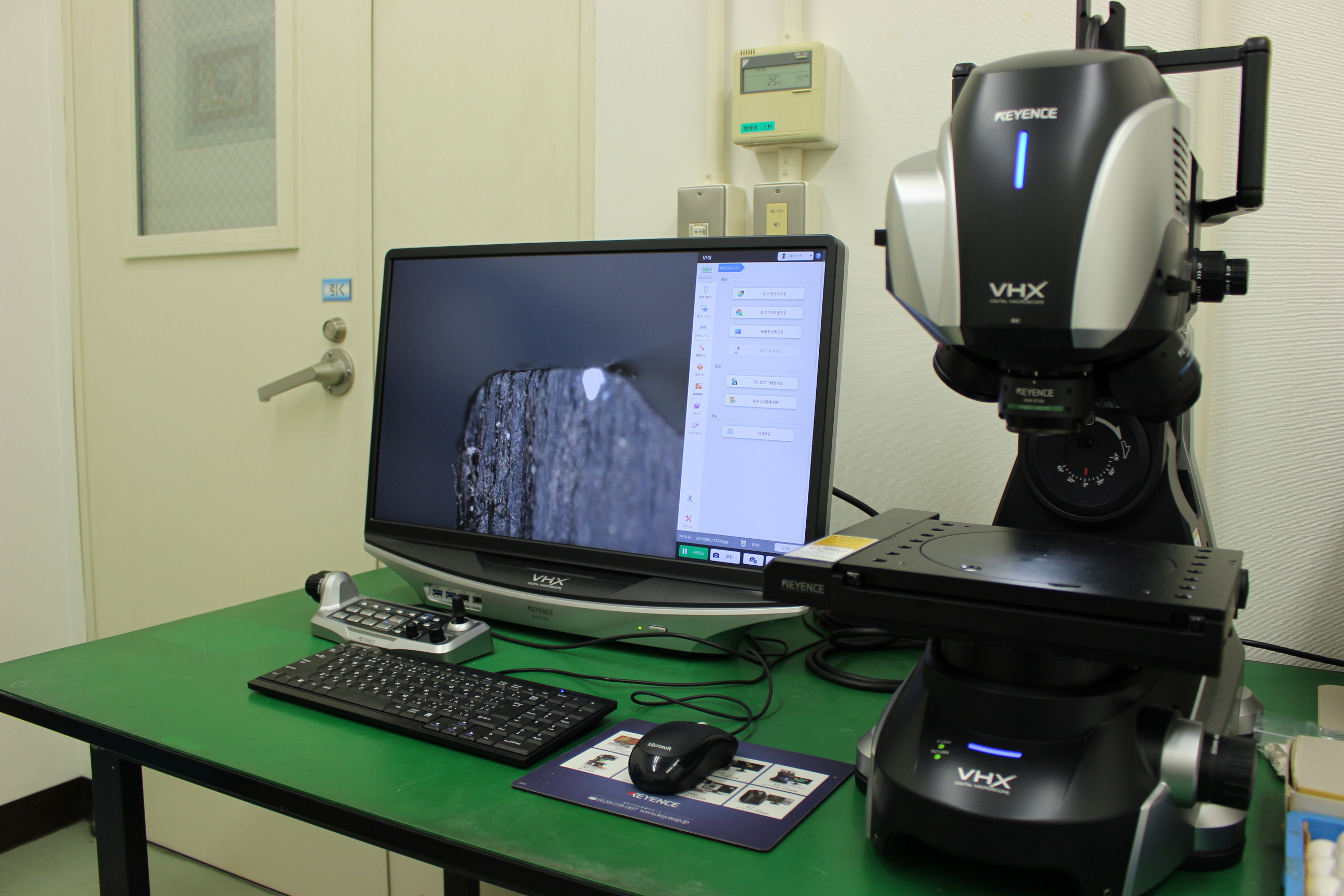

Microscope(5~2500x)

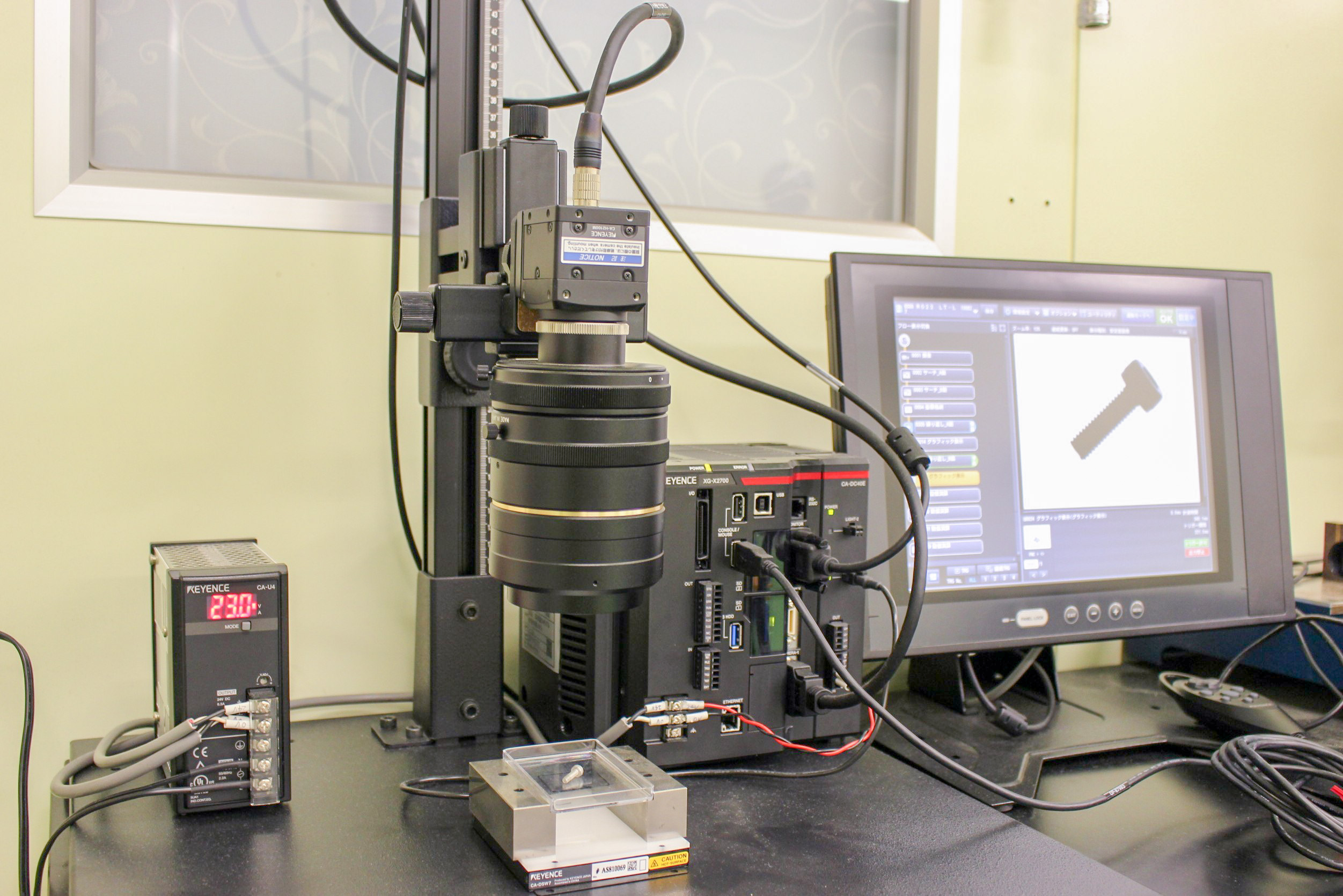

Image Processing Machine